EHS began as a solution provider for process safety challenges within the API manufacturing environment. We have since expanded our portfolio to offer plant wide material handling solutions and process technology support to our customers.

Safety is in our DNA. Our safety and IH background have formed our design culture. Safety has always been, and always will be a core requirement of our design criteria.

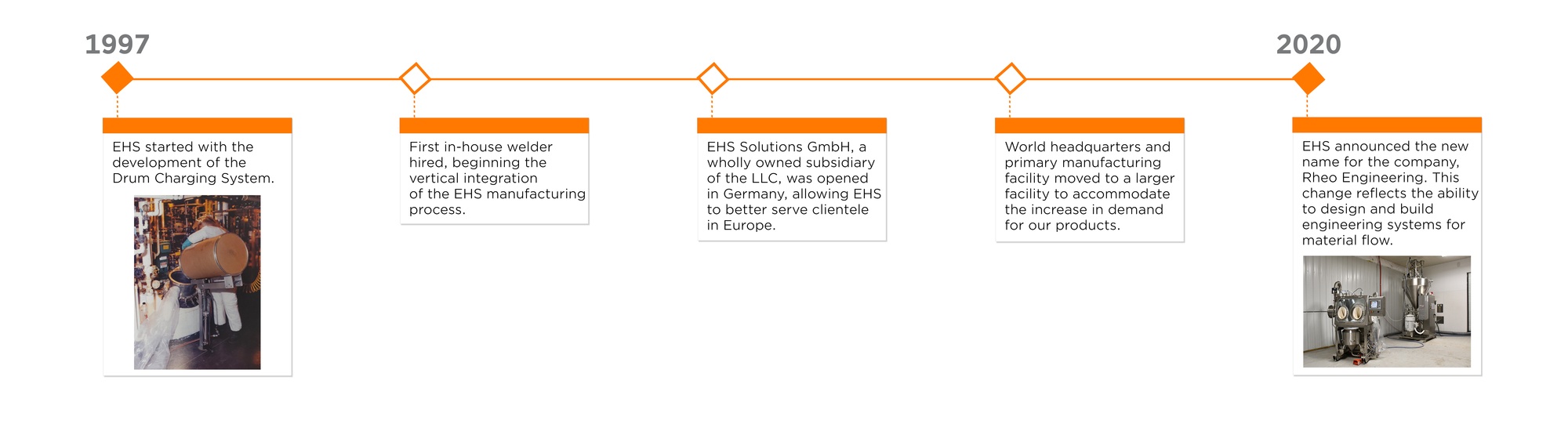

Rheo is the Greek word for flow. It’s a prefix for the word rheology (the study of the flow of materials). As we looked at what our company has grown into, the word Rheo really made a lot of sense. We have become a team of people that apply rheological engineering into every project we engage with. We help our customers with the many challenges of powder and liquid flow; Rheo Engineering simply made sense.

At Rheo Engineering we have 3 core functions: Consult, Design, and Build. These three core functions are what allow us to be a valuable partner to our customers. We fulfil the full meaning of the word engineering: applied science. Our in-house fabrication and mechanical integrators have allowed us to expand our project scope to include complete turnkey solutions for our clients. Our on-site Testing Center allows for both dry and wet testing to establish design confidence in our proposed process solutions. We truly apply the science of Rheology, from design to construction and testing.

Conglomerations of fine particle solids, along with the gaseous space between them and to a lesser extent the encompassed moisture, make up what is simply known as “powder”. This three-phasic system of matter is anything but simple.

Powder is used in nearly every industry where products are made, if not as the final product, then as raw material or an intermediate part of the manufacturing process. In all cases, powder must be handled efficiently and effectively to keep the process running smoothly and ensure a quality product. Without properly considering the multitude of powder characteristics, manufacturing process parameters, and environmental variables, the outcome will most likely be just the opposite. A few of the common issues with powder processing and handling are shown in the image to the right. Applying powder rheology will prevent these problems from occurring and can be used to fix issues already present. But what is powder rheology?

Powder rheology is a phenomenological approach which considers internal and external influences to characterize powder behavior in specific applications.

Learn More!